Overview

The Top Load Case Packer presented here is an efficient fully automated system capable of meeting the requirements of contemporary packaging lines. It can handle up to 1.2 to 2.4 cases per minute which makes it perfect for high-speed, very busy places. This is due to its support of up to 16 kilograms weight, and is constantly used in food and beverages, pharmaceuticals and consumer products industries. This top load design enables accurate and fast packing into slot-loading cases for improved productivity and is easy to maintain, thereby a cost-effective way of improving operations.

Applications:

✔ Food and Beverage Industry: Sustainable for the flow wrapping of food and beverage products, hygiene and preserving the quality of the products.

✔ Pharmaceutical Sector: Effectively and safely store and pack the pharmaceutical products, satisfying the requirement of the industry.

✔ Consumer Electronics: Used in electronics manufacturing for packing of components and other finished products leading to efficiency.

✔ Logistics and Warehousing: Favours the packing and sorting of the products in the distribution centres that helps in efficient space management and organisation.

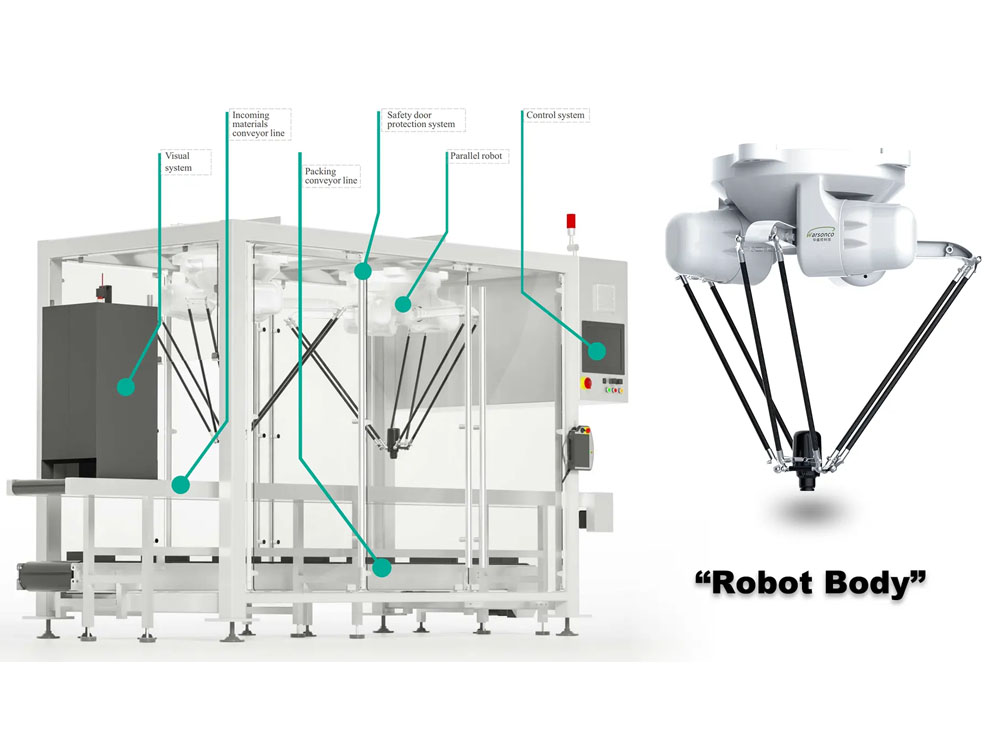

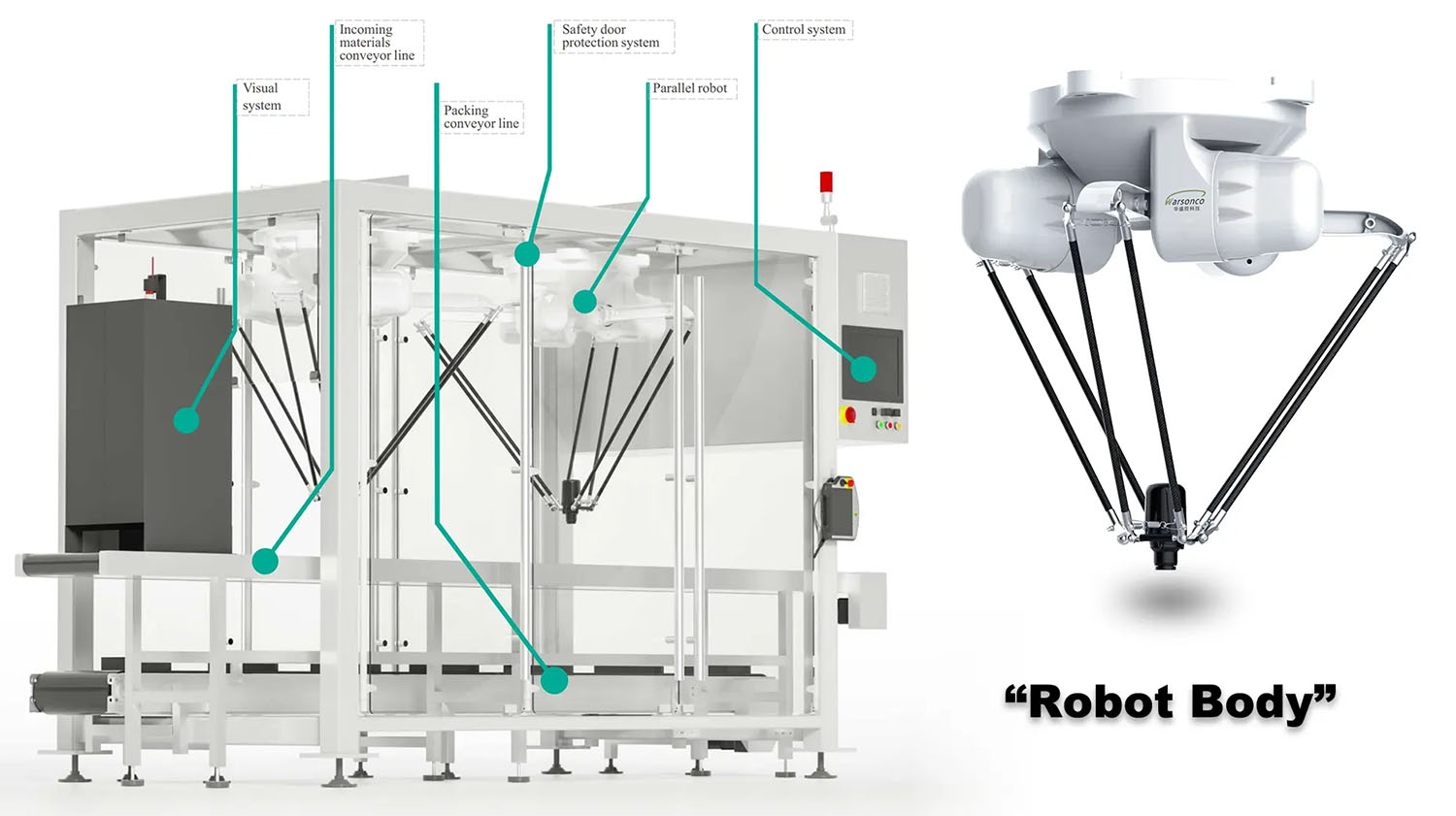

| Configuration | |

| Settings | Brand |

| Servo Motor | Warsonco/Panasonic |

| Machine Reducer | NidecCorporation/Green |

| Controller | Austria KEBA |

The control method utilizes a handheld teaching device, standard control buttons, and signal switches, making it simple to operate and easy to manage.

Features

✔ High-Speed Operation: To carry up to 120 cases per minute, robust performance for companies that handle large production processes.

✔ Cost Effective: Designed to give high utility while being highly operational with minimal cost of operation.

✔ Easy to Operate: Built with an easy-to-use interface so its operation and adjustments can be easily made and thus easier to setup no need to train the users.

✔ Modular System: Enables versatile setups and simple modifications, so that it may accommodate other production requirements and expandability is achievable.

✔ Low Maintenance: Designed for longevity and only minor maintenance, thus providing effective use and minimizing on time spent on repairs.

✔ Certifications: ISO and CE certified company that meets the international standard hence ensuring quality and safety of products.

✔ Versatile Applications: Appropriate to use in Food and Beverage processing industries, Pharmaceuticals, Electronics goods industries.

✔ Warranty and Support: Afford one-year warranty and provides free lifelong technical support, which gives the buyer confidence with the product.

✔ Communication Protocols: Further, it supports MOTRON ICs for Modbus TCP/P and EtherCAT and it supports CAN and RS232/485, thus making it compatible with existing systems.

Specifications

| WSC-M1200 | |||

| Frame Material | Stainless steel | Power | 8kw |

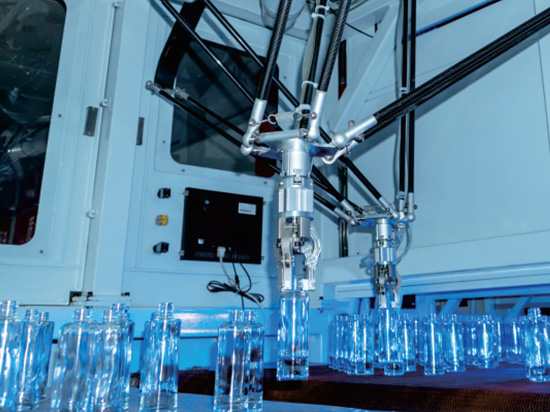

| Max Load | 5kg | Repeat Positioning Accuracy(mm) | ±0.1 mm |

| Angular Positioning Accuracy | ±0.05° | Power Supply | 200-240V 50/60Hz |

| Noise Level | <85db | Protection Rating | IP54 |

| Working Temperature | 1~40°C | Humidity Range | <75%(No condensation) |

| Life Span | 20,000 hours + | Vision System | Hikvision |

| 1-3rd Axis Motor (if) | Panasonic | The Fourth Axis Motor (then) | Panasonic |

| 1-3rd Axis Reducer (if) | Harmonic/Nidec | The Fourth Axis Reducer (then) | Leader Drive |

| Pneumatic Components | AirTAC/SMC | GW | 1200kg |

| Applying Carton Size | L(260-500)*W(200-450)*H(150-400)mm | Applying Product Size | L(10-500)*W(10-450)*H(5-100)mm |

| Carton Conveyor | H: 540mm | Incoming Conveyor | H: 950mm |

| Applying Case Size | L100*W100*H100 mm, L480*W400*H400 mm | Size | L4227*W2678*H2617mm |

| Carton Erector Speed | 8Carton/minute | Delta Robot Speed | Up to 120PPM( speed vary from the product, products weight) |

| Features | Carton Erector, case sealer, top load case packer in one system | ||