Overview

The advantages of the Robot Case Packer are that it is an automated packaging equipment which will bring about a major technological change in the packaging industry. This new elaborate system can perform various tasks such as packing, sorting and orientation all within one efficient machine. It reduces considerably the need of handling and relying on the human operator and increases the overall automation of the packing line by automating the pick and place, forming, folding lids, sealing bottoms, and packing. Such design enables high-load operations and accuracy making it a must-have for any manufacturing and packaging line.

Applications

Manufacturing Facilities: Perfect for packing applications in mass production industries, helping to increase throughput and decrease human resource expenses.

✔ Distribution Centers: Simplifies handling of products in that it simplifies the packing and sorting of products,, easing the workflow from manufacturing to distribution.

✔ Food and Beverage Industry: Thus, proper and clean packaging of foods and beverages is ensured in line with the food industry standard.

✔ Pharmaceutical Sector: Responsible for packaging pharmaceutical products with precision, keeping with the policy and legal guidelines.

✔ Consumer Goods: It effectively accommodates different consumer goods such as electronics and household products hence enhancing flow of productivity in several industries.

✔ Logistics and Warehousing: Enhances the methods of packaging and sorting goods in the stores, hence improving space utilization as well as efficiency.

| Configuration | |

| Servo Driver | Warsonco |

| Controller | Keba |

| Reducer | Laifual |

| Pneumatic System | Air TAC |

Features

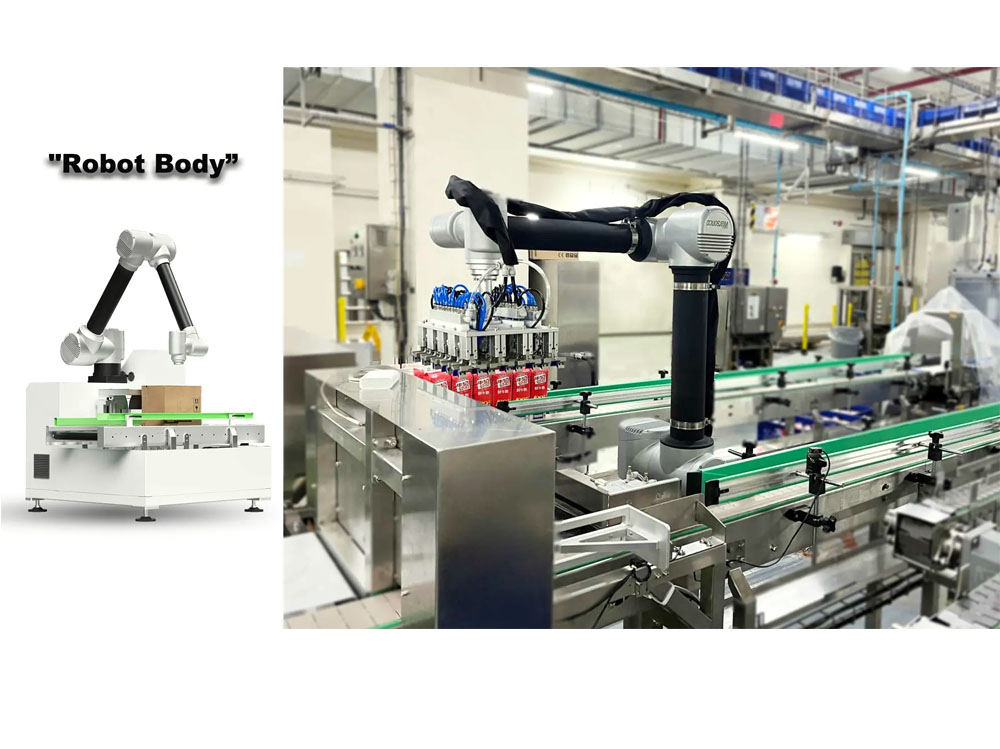

✔ Collaborative Robot Body: It includes a powerful robotic arm built to pack items deftly and quickly.

✔ Human-machine control Interface: This interface offers an easy-to-use structure for controlling and monitoring the performance of a specific machine.

✔ Stainless Steel Packing Roller Conveyor: This eliminates the chances of damages that may negatively impact the durability of the products and provides hygiene as the products are being packed to be moved to the next station.

✔ Fixed Base: Stability and reliability: This is a chance to make the base more stable and to add more reliability to the whole machine.

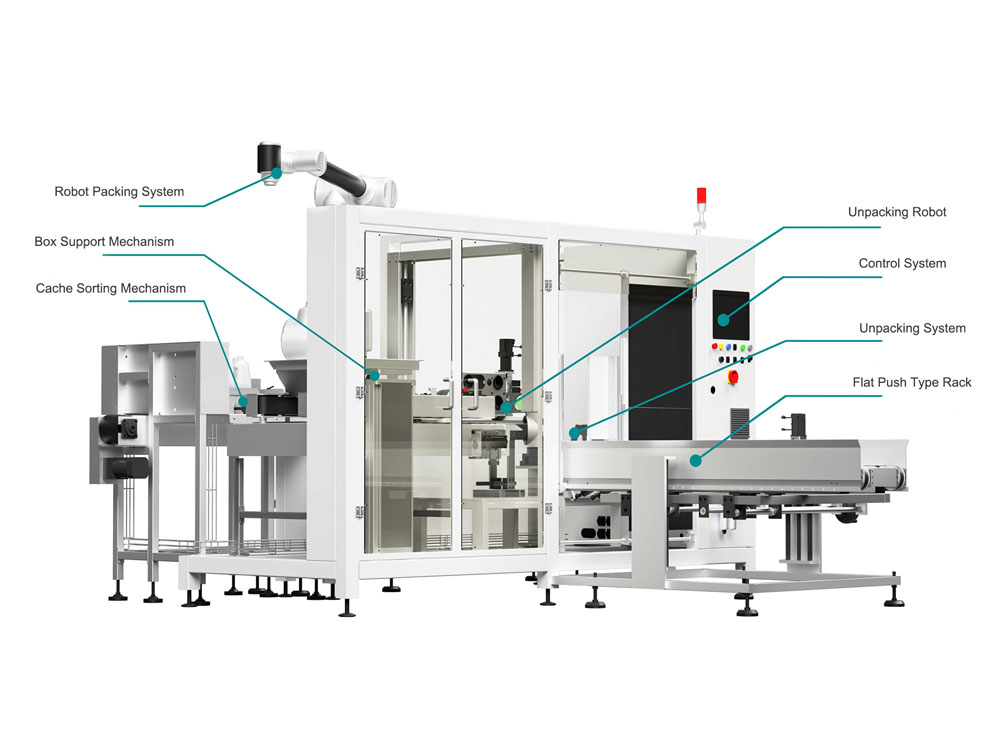

✔ Case Erecting Mechanism: It can automatically form and set up cases, simplifying packaging operations.

✔ Collaborative Box-Opening Robot Paperboard Storage Tank: This tank assists in easy storage and access of the paperboard used for opening the box.

✔ Rack Width Adjustment frees up space for boxes of different sizes, enabling easy organization of these boxes in a size-efficient manner.

✔ Press Plate Height Adjustment: Allows proper adjustment of the height of the press plates to provide adequate sealing.

✔ Suction Paperboard Suction Cup Assembly: Furnishes the right protection to paperboard to ensure formation of good quality boxes.

✔ Output Cardboard Belt Width Adjustment: This enables the company to accommodate different sizes of cardboard, which is the company's most used raw material.

✔ Cardboard Bottom Forming Mechanism: This mechanism forms the bottom part of cardboard boxes, and when operated automatically, it helps in packing.

✔ Bottom Sealing Mechanism: This mechanism tightly closes the bottom ends of the boxes to guarantee the preservation of the products’ quality during transportation.

Specifications

| Collaborative packing machine |

|||

| Maximum Power | 3.5kw | Packing Speed | 6-8 Cases/min |

| Rated Load | 25kg(with out robot gripper) | Dimension | L1635mm*W1244mm*H2020mm |

| Collaborative Robot | WSC-XZ30 | Total Weight | 1000kg |

| Applicable Product Size | L(50-300)mm*W(50-280)mm*H(35-100)mm | ||

| Applicable Carton Size | L(280-500)mm*W(150-400)mm*H(150-400)mm | ||

| Applicable Industries | Pharmaceutical, daily use chemical, food and other industries | ||

| Main Material | Stainless steel SUS 304/White baking paint Q 235 | ||

| Collabrative unpacking and packing all-in-one machine (case erector+case packer+case sealer) | |||

| Maximum Power | 8.2kw | Packing Speed | 6-8 Cases/min |

| Rated Load | 16kg/20kg (with robot gripper) | Dimension | L2970mm*W3420mm*H1850mm |

| Collaborative Robot | WSC-XZ16/WSC-XZ20 | Total Weight | 1800kg |

| Applicable Product Size | L (50-300)mm*W (50-280)mm*H (35-100)mm | ||

| Applicable Carton Size | L (280-500)mm*W (250-400)mm*H (150-400)mm | ||

| Applicable Industries | Pharmaceutical, daily use chemical, food and other industries | ||

| Main Material | Stainless steel SUS 304/White baking paint Q 235 | ||