Parallel Robots Simulation: Optimize Performance & Design

What is Parallel Robot Simulation?

A parallel robot is defined as a robot that features several independent actuators that connect to a single platform. Whereas serial robots require operation in a sequence (one joint moves, then another joint move, and so on), parallel robots operate in such a way that independent movement is possible and even jointed arms can move at the same time. This configuration allows for more accuracy, increased speed of operation, and improved force-to-weight ratios. It's no surprise that parallel robots are found in industrial manufacturing automation, medical surgery, and more. Parallel robots simulation means creating a model of the devices and running tests on devices in a sandboxed, simulated environment.

Why Simulation is Important for Parallel Robots?

Cost-Effective:

Prototyping and testing physically is avoided, thus saving time and money during the development phase.

Effective:

Design can be perfected via simulation to improve elements like speed, accuracy, and power consumption.

Safety Before Reality:

Testing safety components and operational limits, and expensive design flaws can occur virtually before any adjustments need to be made in reality.

No Lag Testing:

Engineers, thanks to technology for real-time simulation, can test how a robot works and all its operational limits in differential stimuli without lag

Core Technologies Behind Parallel Robots Simulation

Kinematic Simulation:

Understanding a Robot's Movement Kinematic simulation is an essential step to parallel robot simulation. By exploring the relationship between different links, joints, and actuators, engineers can generally predict how a robot will move. Kinematic simulation establishes inverse kinematics and forward kinematics for parallel robots.

• Inverse Kinematics: The process used to determine what joint angles are needed to position an end-effector in a given position.

• Forward Kinematics: The process used to determine how an end-effector is positioned and oriented given joint specifications. When these processes are simulated, it gives engineers the ability to see movement onscreen and adjust parts before any part is created.

Dynamic Simulation: Understanding Forces in Action

Dynamic simulation adds to kinematic simulation with forces, torques, and inertia that would not be used unless they were naturally occurring. In the real world, friction, weight, and outside forces engage work effort cycles, for example, testing a parallel robot for force reaction feedback to see if pushed/pressed, to understand resistance before it operates on a vertical plane or in a set perspective for medical or industrial application.

Workspace Analysis: Determining Where the Robot Can Go

A workspace analysis is conducted to create the intended working area of the range of motion. Configuration analysis knows what the range of intended motion is, even tracking singularity (inability to maintain control) if the robot gets to those areas. Poor workspace design creates non-functioning areas; good workspace design ensures the robot can operate better through proper placement.

Parallel Robot Simulation Software

The proper parallel robot simulation software is necessary to provide a successful simulation of parallel robots. Here are some popular software options for robotic endeavors.

ROS (Robot Operating System)

ROS is an open-source framework for the development of robotic applications. Using ROS, engineers can simulate parallel robots using existing packages for kinematics modeling, control interfaces, and visualization. It's especially helpful in constructing digital twins of parallel robots for implementation and testing purposes in real-time.

MATLAB and Simulink

These coding and dynamic system simulation software provide an opportunity for engineers to create their own inverse and forward kinematics, dynamics simulations, and control strategies. Simulink allows for the graphical rendering of parallel robot component interactions as well.

Gazebo and Unity:

Gazebo is a 3D simulation environment with integrated ROS used for physics and simulation reality. It's particularly useful for simulating and testing motion control algorithms. Unity is a game engine and the most customizable simulation environment. It boasts the most guided virtual prototyping integration with real-time, responsive feedback.

Applications of Parallel Robots Simulation

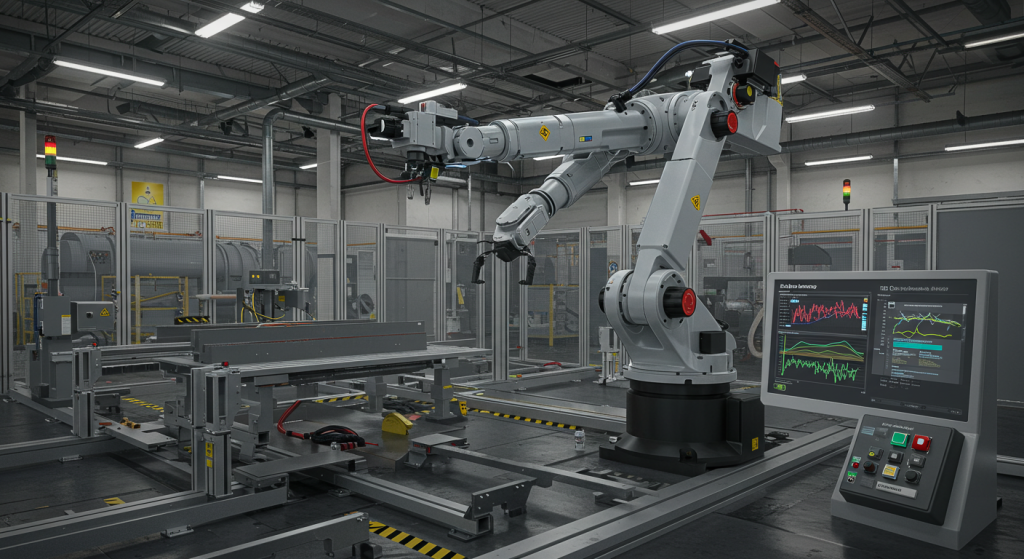

Industrial Automation

Industrial automation depends on the simulation of parallel robots for successful operation, whether it's for pick-and-place, assembly, packaging, and more. The simulation helps ensure success with high speeds, accuracy, and safe handling of applied materials.

Medical Robotics

Medical robotics parallel robots require simulation when it comes to surgical medical robotics. It helps develop such robots for minimally invasive procedures with the need for force feedback and precise motion control in sensitive areas of existence. This matters for surgical medical robotics because one error can have the most devastating results.

Aerospace and Manufacturing

In the aerospace industry, parallel robots are used for assembly and testing. Aerospace is very precise, so simulating a parallel robot in its theoretical space can help researchers understand if such a robot can function in the precision assembly of aerospace components. The same is true for the simulation of manufacturing. Aerospace and manufacturing jobs require speed and precision for repetitive tasks, so simulation can determine best practices before applying them in the real world.

Motion Platforms and Entertainment

Finally, parallel robots are used for entertainment in motion platforms. For example, virtual reality uses parallel robots to simulate differing levels of resistance points. Therefore, simulating parallel robots helps determine force-feedback patterns and replication needs before placing them into the operating models.

The Future of Parallel Robots Simulation

As the demand for robots across fields grows, so will the demand for simulation of parallel robots. More sophisticated systems will be able to create simulations for better opportunities for designs. In addition, as digital twins become a reality, it will be easier for computers to simulate in the theoretical space, in real time with real parallel robots.

In addition, as industries are always on the lookout for energy-efficient robots with additional safety features, simulation will begin to offer systems that can be customized for every need.

Conclusion

The opportunity to simulate parallel robots is an excellent way to guarantee productivity, safety, and operation before going live. Whether they're in warehouses, performing surgery, in the sky, or helping you win a video game, simulation allows for the best application of parallel robots. The future of robotics is assured through successful simulation systems. For more information regarding parallel robots and ways to help with your simulation requirements, visit us at Warsonco Robot.