✔ Collaborative Palletization: It restructures ease of use through operations and how it can interface with current systems.

✔ Quick Installation and Re-Adjustment: The full installation and re-calibrating period can be completed in less than 2 hours, thus ensuring that the least amount of time is spent during the conversion process.

✔ Fast Path Setup: They can be configured and brought up in under five minutes, so you can quickly adjust the flow to meet the change in production rate.

✔ High Stacking Speed: The potential to pick from 8 to 11 boxes per minute will help manage the large number of products.

✔ Extensive Path Capacity: Handles up to 800 staking paths, giving application designers potential for wide-stacking applications.

✔ Maximum Tray Size: It holds trays up to 1400mm x 1400mm, allowing for a variety of products and arrangements.

✔ Dual Product Stacking: This is designed to stack two products simultaneously, improving efficiency and throughput.

✔ Label Orientation Function: This product comes with a label orientation function that helps in the right positioning of products, especially when placing them on pallets.

Overview

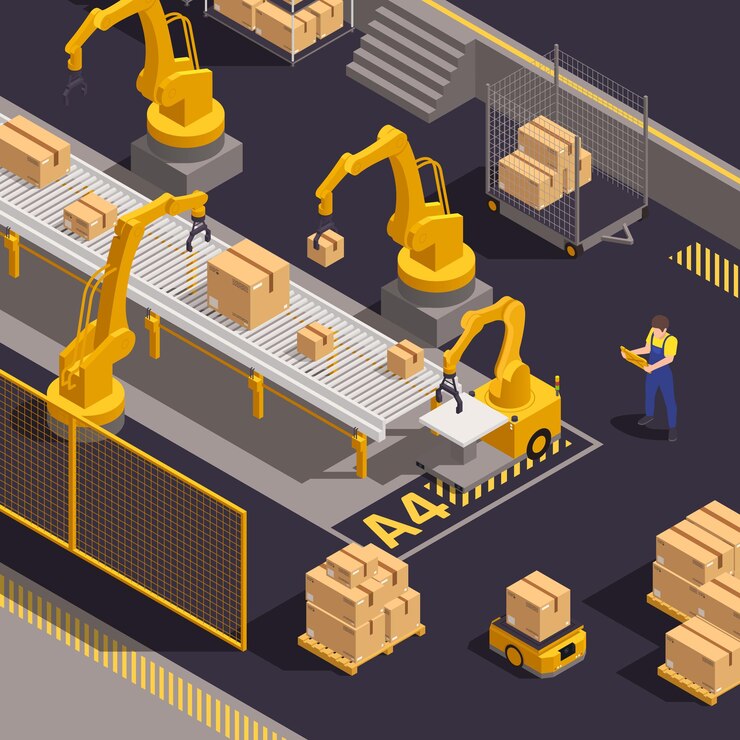

The specific product of collaborative robots that has been developed by the German manufacturer Ubimax is called Palletizing Cobots WSC-MD16, it is aimed at the further democratization of the use of classical palletizing, taking into account all the modern requirements of the production process and global logistics chains. Built to be highly efficient in its operation and easy to deploy, this cobot assists in stacking efficiently with incredible speed and accuracy from this picture. It is, therefore, perfectly suitable for industries interested in increasing their operational efficiency, increasing capacity, and handling large amounts of products with short implementation time.

Applications

✔ Manufacturing Facilities: Improves the process of palletizing in that it can be set up quickly and offers high rates of stacking which are useful with a large number of products.

✔ Distribution Centers: Enhances product arrangement and movements and streamlining of product flows from production to distribution.

✔ Food and Beverage Industry: Responsible for arranging packaged food and beverages most appropriately regarding hygiene measures and general orderliness.

✔ Pharmaceutical Sector: This sector is responsible for palletizing sophisticated pharmaceutical products and ensuring that the application meets regulatory requirements.

✔ Consumer Goods: Effectively integrates several consumer goods technology products and other household items to enhance effectiveness and efficiency.

✔ Logistics and Warehousing: Helps to maintain adequate flow and positioning of goods within various facilities such as warehouses hence enhancing productivity

Palletizing Workstation Expansion Configuration Scheme

✔ Lidar Sensor: Contact-free and flexible in setting detection distances. It alerts and slows down when approaching the yellow zone, and stops immediately upon entering the red zone.

✔ Light Curtain Sensor : Stable performance, strong anti-interference capability, high sensitivity, quick response, and long service life.

✔ Safety Fence: Provides physical protection, ensuring safety and reliability.

| Configrations | ||

| Servo Motor and Controller | Panasonic | Warsonco/Made in China brand |

| Reducer | Nidec-Shimpo/LaifualDrive | |

| Controller | KEBA | |

| Pneumatic Components | AirTAC | |

| Optional Components (Standard/Customized) | ||

| EOAT | Pneumatic Gripper | Sponge Vacuum Sucker |

| Weight: 4kg | Weight: 4kg | |

| Gas Consumption: 400NL/MIN | Gas Consumption: 450NL/MIN | |

| Pneumatic Supply: 0.6-0.8MPa | ||

| Infeed Roller Conveyor | Material:ss304, Size: L1000xW500xH600+50mm, Weight: 45kg | |

Features

What parameters or information do you need to provide?

✔ Production Lines:

- How many production lines need our robots?

- Are the lines single or double?

- Are the boxes the same size on each line?

✔ Box Details:

- What are the dimensions and weight of your boxes?

- How many boxes per minute come in?

✔ End-Effector Customization:

- We'll adjust the end-effector to handle your boxes based on their size, weight, and speed.

- Special products might need custom end-effectors.

✔ Palletizing Patterns:

- Do you have existing palletizing patterns? If so, please provide them.

✔ Product Samples:

- Our robots undergo testing before shipment. Please provide samples if you have them.

✔ Training:

- We recommend visiting our factory for free training on robot operation. We'll adjust the robots to your satisfaction before shipping.

Specifications

| Palletizing Cobots WSC-MD16 | |||

| Load | 16kg | Working Radius | 1900mm |

| Pallet Size | 1400mm*1400mm | Vertical Distance | 2400mm |

| Stacking Speed | 8-11pcs/min | Repeated Positioning Accuracy | 0.04 |

| Communication Mode | TCP/IP | Level Ip | IP54 |

| Temperature Range | 0-55℃ | Maximum Power Dissipation | 3.3kw |

| Applicable Power Source | 200-240V, 50/60HZ, 1Phase | Weight | 300kg |

| Floor Area | 1505*1716mm | Supported Protocols | Modbus-TCP, EtherCAT, CAN, RS232/485 |

| Package Size | 2100*1520*1600mm | ||