Overview

The Delta Parallel Robot is a cutting-edge automation solution designed for high-speed precision tasks in various industrial environments. Capable of performing up to 120 cycles per minute and handling payloads of up to 12KG, this robot is ideal for tasks requiring both speed and accuracy. Its large travel range allows for greater flexibility in applications, making it a versatile tool for industries that demand rapid and reliable robotic assistance.

Engineered with advanced parallel kinematics, this Delta robot is optimized for fast and efficient pick-and-place operations, packaging, and assembly processes. Its robust design ensures stable performance even at high speeds, while its precision control allows for the meticulous handling of delicate components.

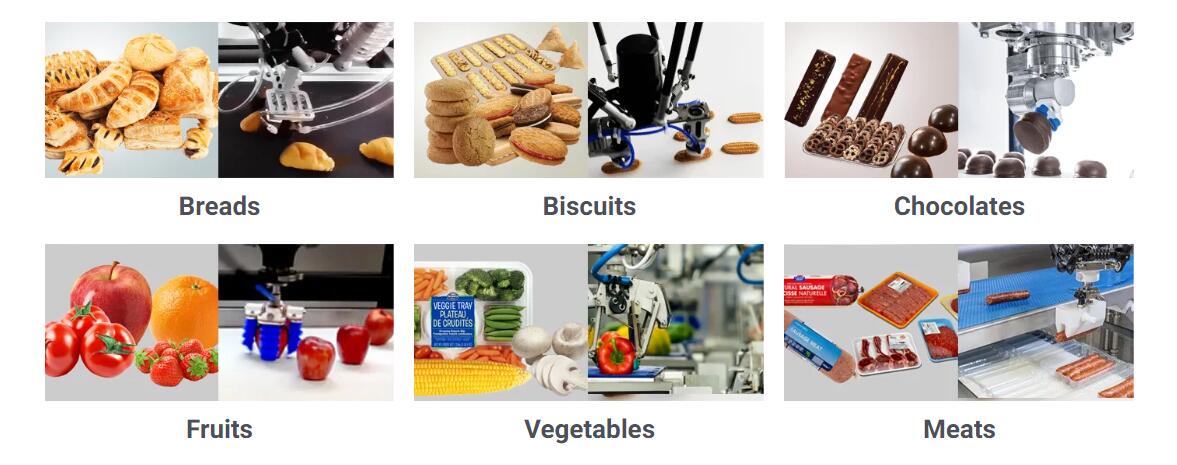

Working Range (mm)

| Configuration | |

| Settings | Brand |

| Servo Motor | Warsonco/Panasonic |

| Machine Reducer | Nidec corporation/green |

| Controller | Austria KEBA |

Applications

The Delta Parallel Robot is versatile and can be deployed across a wide range of industries for various applications:

✔ Packaging: Ideal for high-speed sorting, packing, and palletizing of products, ensuring efficiency in packaging lines.

✔ Pick-and-Place Operations: Perfect for precise pick-and-place tasks, such as handling small components in electronics manufacturing or food items in the food processing industry.

✔ Assembly: Suitable for assembling parts in automotive, electronics, and consumer goods manufacturing, enhancing accuracy and reducing assembly times.

✔ Pharmaceuticals: Ensures the safe and precise handling of delicate pharmaceutical products, maintaining product integrity and compliance with industry standards.

✔ Food and Beverage: Provides fast and accurate sorting and packaging of food items, ensuring consistent quality and reducing the risk of contamination.

Features

✔ High-Speed Operation: With the capability to perform 60 to 120 cycles per minute, this robot significantly enhances productivity in high-demand environments, reducing cycle times and increasing throughput.

✔ Strong Payload Capacity: Handles up to 12KG, making it suitable for a wide range of products, from lightweight components to heavier items.

✔ Large Travel Range: The robot’s extensive travel range allows it to cover more area, providing greater flexibility in positioning and operation within the production line.

✔ Precision and Accuracy: Advanced control systems ensure that the robot executes tasks with exceptional precision, minimizing errors and improving product quality.

✔ Durable and Reliable: Built with high-quality materials and components, this Delta robot is designed to withstand the rigors of continuous operation in industrial settings.

✔ Compact and Efficient Design: Despite its capabilities, the robot features a compact footprint, making it easy to integrate into existing production lines without requiring significant space.

✔ User-Friendly Interface: The intuitive control system allows operators to easily program and manage the robot’s functions, ensuring quick setup and minimal training requirements.

Specifications

| Parameters | |||

| Model | WSC-1000D-L3 | WSC-1000D-L8 | WSC-1000D-L12 |

| Power Rating | four-axis | four-axis | four-axis |

| Max Load(kg) | 3kg | 8kg | 12kg |

| Standard Cycle Time(s) | 0.4 seconds /cycle (25/305/25 mm) | 0.4 seconds /cycle (25/305/25 mm) | 0.4 seconds /cycle (25/305/25 mm) |

| Repeat Positioning Accuracy(mm) | ±0.05mm | ±0.05mm | ±0.05mm |

| Angular Positioning Accuracy | 0.05° | 0.05° | 0.05° |

| Power | 220V-240v 50/60Hz | 220V-240v 50/60Hz | 220V-240v 50/60Hz |

| Power Rating | 2.5kw | 3.5kw | 5kw |

| Noise Level | <75db | <75db | <75db |

| Protection Level | IP54 | IP54 | IP54 |

| Motor Method | AC servo drives | AC servo drives | AC servo drives |

| Demonstrator | 7inch demonstrator | 7inch demonstrator | 7inch demonstrator |

| Vision Positioning Module | Optional configuration (130W camera, lens, light Source) | Optional configuration (130W camera, lens, light Source) | Optional configuration (130W camera, lens, light Source) |

| Operating Instructions | PTP、LINE、PICK、PLACE | PTP、LINE、PICK、PLACE | PTP、LINE、PICK、PLACE |

| Installation Method | Inverted | Inverted | Inverted |

| Robot Weight | 72kg | 72kg | 72kg |

| Playlay load 0.1kg | 0.42s | ||

| Playlay load 1kg | 0.49s | ||

| Working Temperature | 1-40°C | ||

| Humidity Range | 5%~90%(No condensation) | ||

| Life Span | 20000 hours+ | ||

| GW | 73kg | ||

| 1-3rd Axis Motor (if) | Panasonic | ||

| The Fourth Axis motor(then) | Panasonic | ||

| 1-3rd Axis Reducer/Gearbox(if) | Harmonic/Nidec | ||

| The Fourth Reducer/Gearbox(then) | Leader drive | ||

| Controller/PLC | Keba | ||

| HMI | Keba | ||