Case Packer(6 Results)

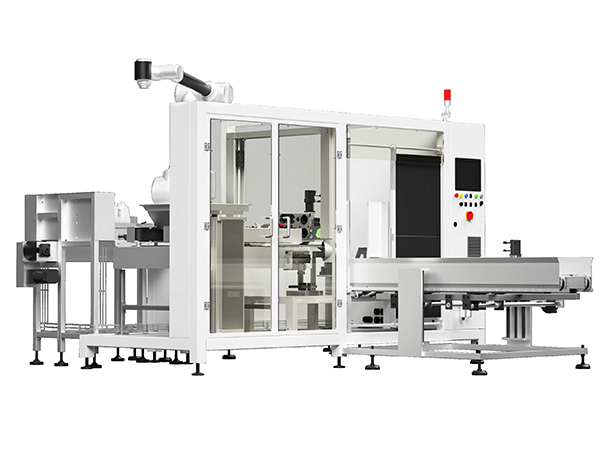

WSC-ZX-RD80T/-RD80B

Robotic Case Packer,Integrated Unpacking, Packing, And Sealing Machine

-

Single robot Speed:60-120times/minute

-

Frame:Baking paint(white)/Stainless steel

-

Maximum power:15KW.

-

Boxes packing speed:10times/minute

-

Visual positioning/High accuracy(+/-0.05mm)

-

Automatic Unpacking ,sorting ,packing and sealing

More Info

WSC-ZX-RD80T/-RD80B

Robotic Case Packing,Integrated Unpacking And Packing Machine

-

Single robot Speed:60-120times/minute

-

Frame:Baking paint(white)/Stainless steel

-

Maximum power:12KW

-

Box packing speed:10times/minute

-

Visual positioning/High accuracy(+/-0.05mm)

-

Automatic Unpacking ,sorting and packing

More Info

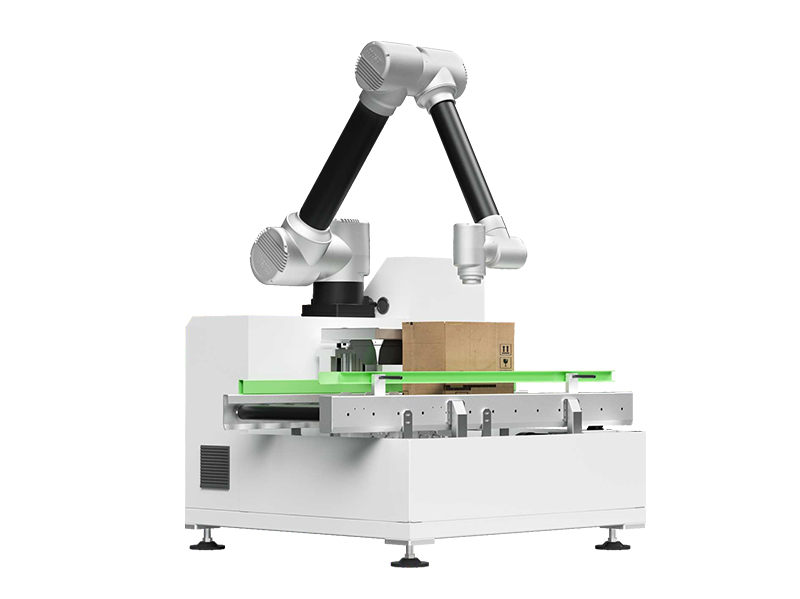

WSC-KZ-XZ16 /-XZ20

Robot Case Packer,Collaborative Unpacking and Packing 2 in 1 Work Station

-

Unpacking Speed: 6-8times/minute

-

Packing Speed: Fast Speed Up To 22times/Minute(Up To The Product Loadweight)

-

Specifically designed for packing heavier products

-

Maximum power:8.2kw

-

automatic unpacking and packing

-

Main frame :baking paint (white)/stainless steel.

More Info

WSC-ZX-XZ25

Case Packer Robot,UP 16KG-40KG-WSC-ZX-XZ25

-

Packing Speed: Heavy Product (6-8times/Minute)/Light Product(Up To 22times/Minute)

-

Maximum Power: 3.5kw

-

Rated load: 16-40KG

-

Applicable product size:L:50MM-300MM,W:50MM-280MM,H35MM-100MM

-

Applicable carton size:L:280mm-500mm,W:150mm-400mm,H:150mm-400mm

-

Main frame :baking paint (white)/stainless steel.

More Info

Why Choose Robobeen Robotics?

Rich Experience in Robotics Development

Quality

We possess multiple invention patents and trademark brands, and have obtained CE and ISO certifications.

Customized Service

We offer a variety of packaging solutions for you to choose from, tailored to your specific needs.

ROI Benefit

Achieve return on investment within 1-2 years through highly adaptable production processes.

FACTORY

We have our own CNC machining center and fully automated production lines.

High-precision Robots, Customized to Your Needs

Due to our advanced technology, our robots offer the fastest return on investment.

One of the models that we present in our Case Packers series is the Collaborative Palletizing Workstation. It transmits power at high speeds with great precision and, at the same time, is surprisingly easy to control. Other dynamic aspects are material counting, stacking, and sorting that can be adjusted according to packaging requirements by means of program changes. This workstation can be designed to blend with existing mechanical systems and manufacturing conveyor systems or be used as a standalone; it is a fully automated system. Integrated with intelligent vision systems for position sensing and object tracking, as well as adaptive gripping, the workstation further enables automatic error checking and, therefore, the reliability of operations. It is easy to install due to its modular features andand does not require a lot of space on the production floor. The fewer components, the simpler it is to maintain and the cheaper it is, making it an economical innovation to add to any production line.

Learn More